Focus on Target

Enjoy The Journey

I did not know what to do with myself.

Music school, carpentry college, writing tales, ballroom dancing, 2-years army service(compulsory at that time), street musician, studied economics, tv broadcast, director’s assistant, video editor. Something was always missing…

It started to get clearer after watching Terminator 2.

HOW did T-1000 rise from that floor?

I dropped economics and started journalism(it was suppose to help me with my TV-career), and bought 3 tomes of 3D Max Bible (thank you, Mom).

Please find below some images from my journey in 3D.

Sorry for the “greedy” explanation - I hope you want to find out more in person.

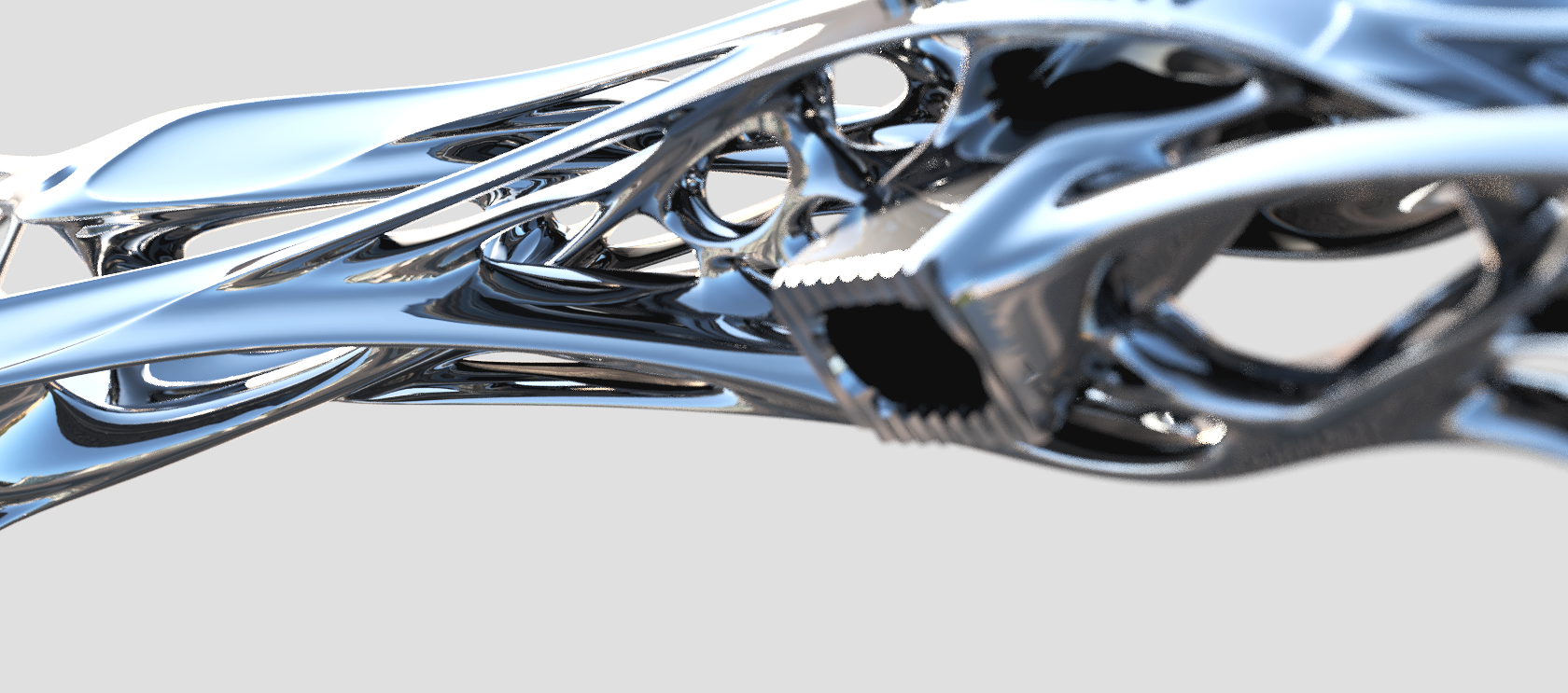

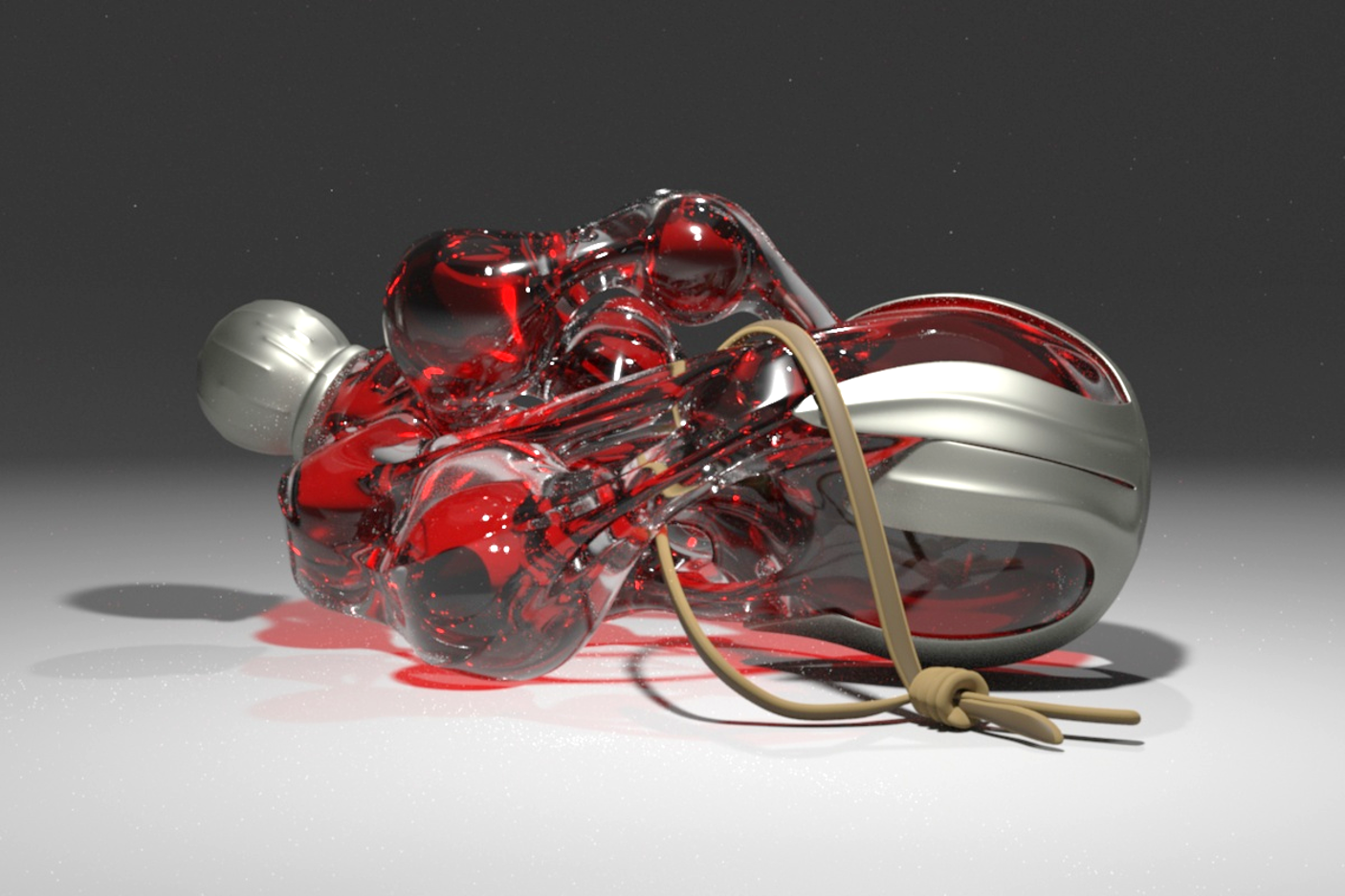

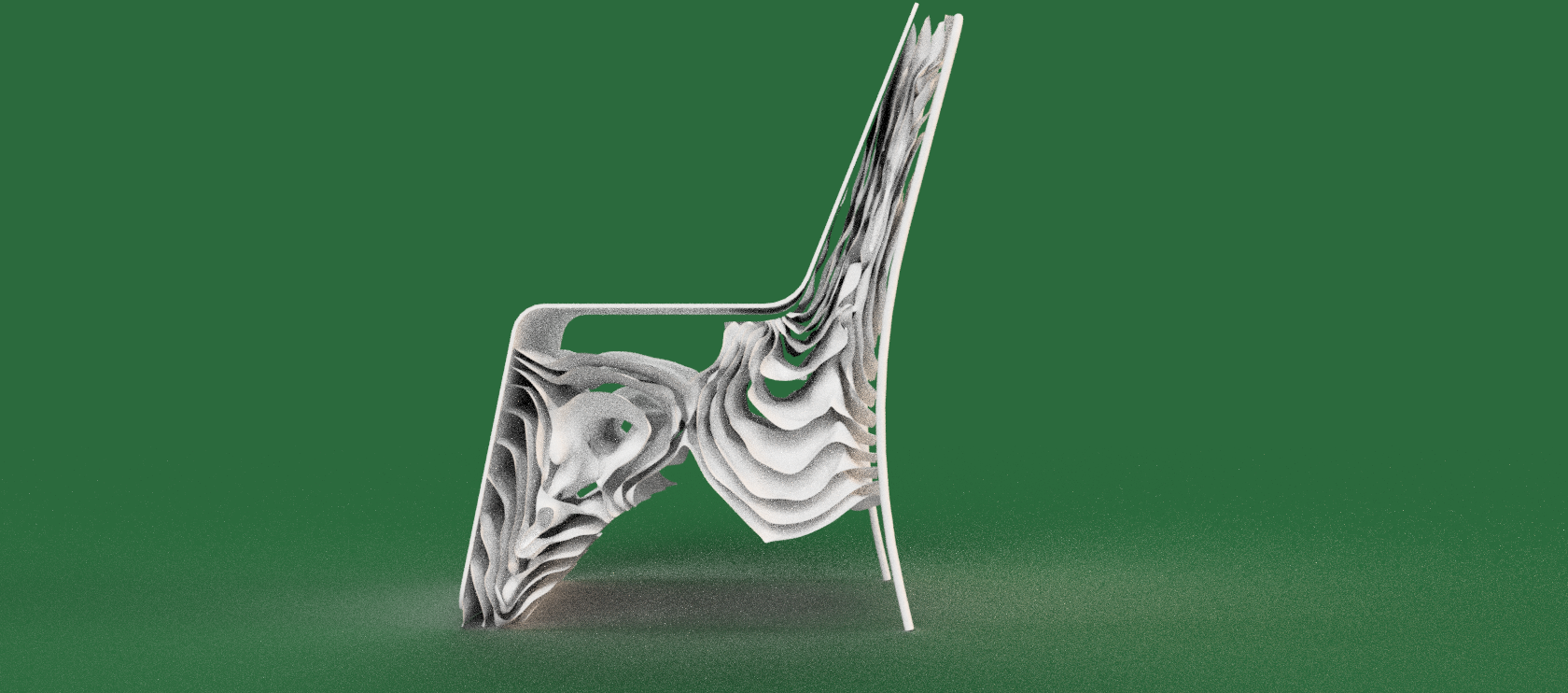

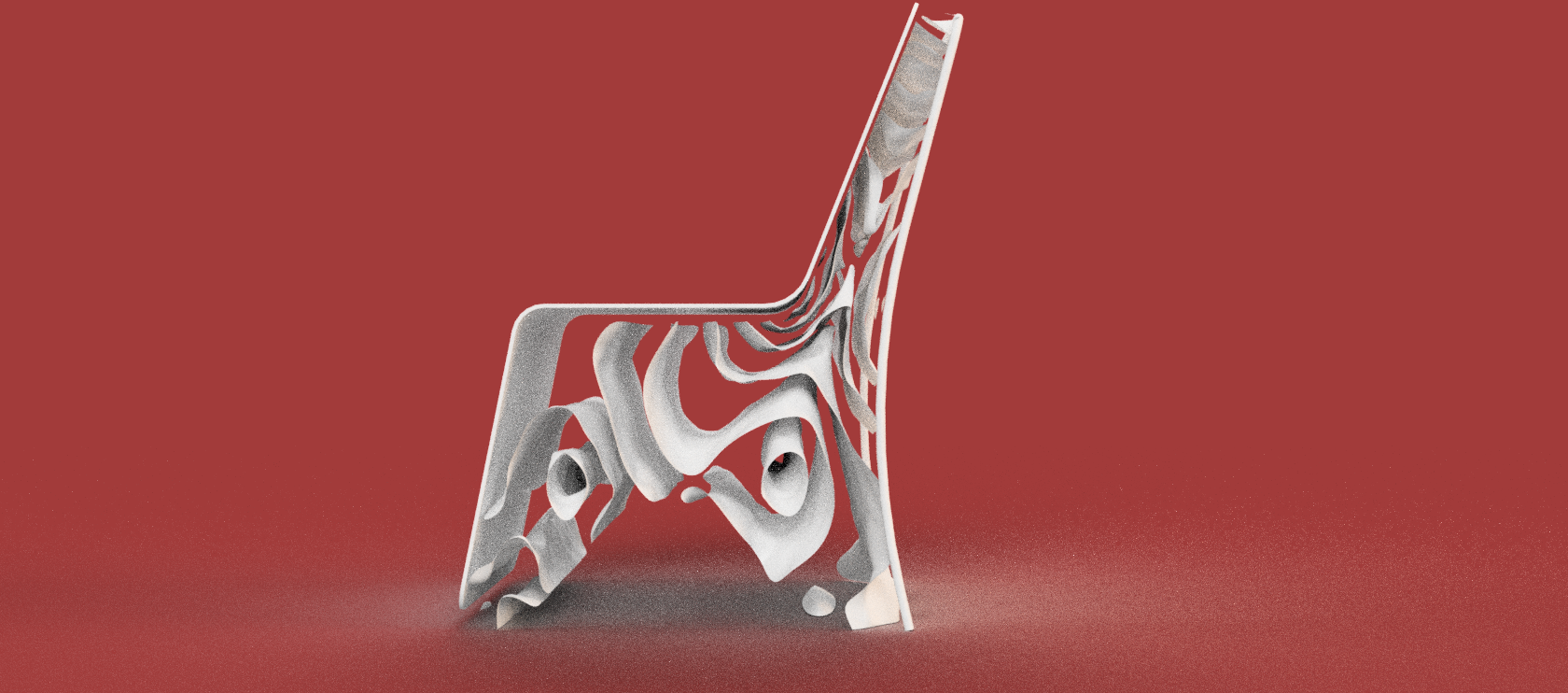

Inspired by liquified T-1000, but I am not very keen to do liquid simulation today - it’s a tough task to meet the deadline!

But, it feels like liquid structures are quite an influence for my shapes.

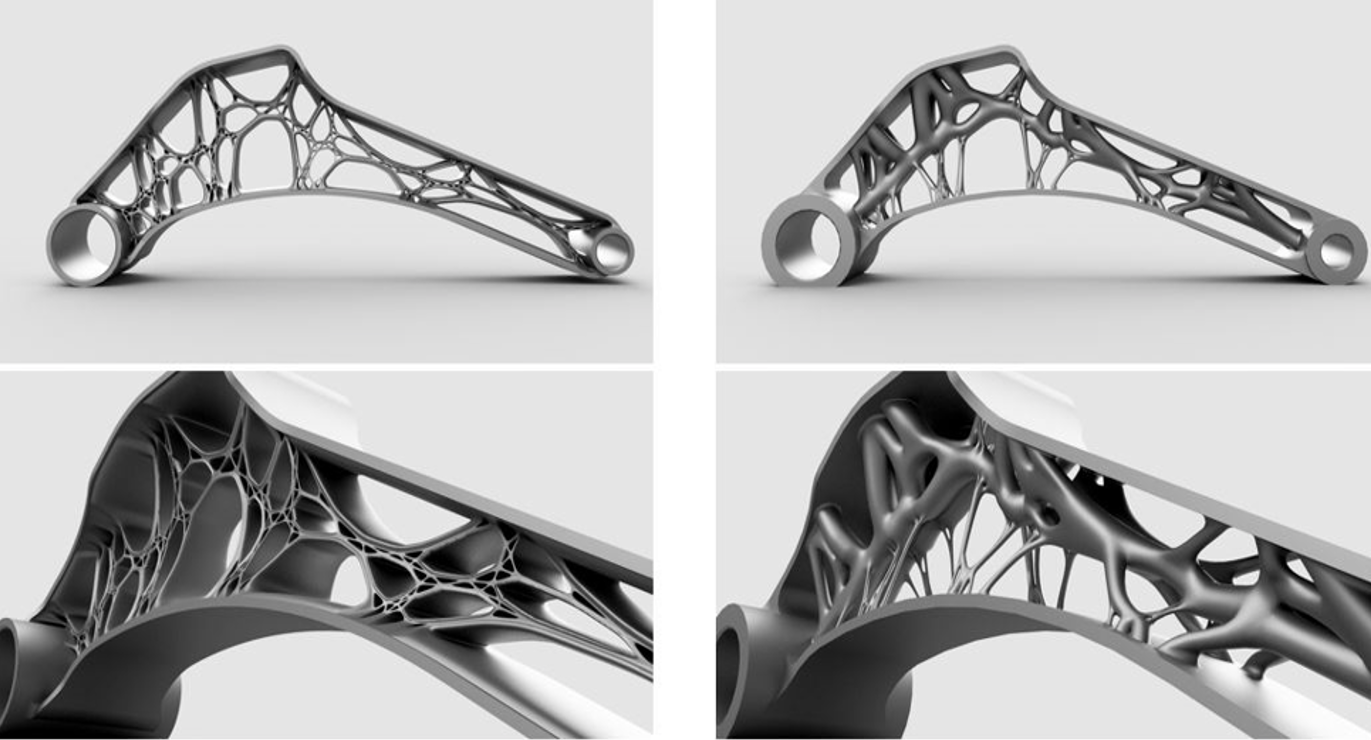

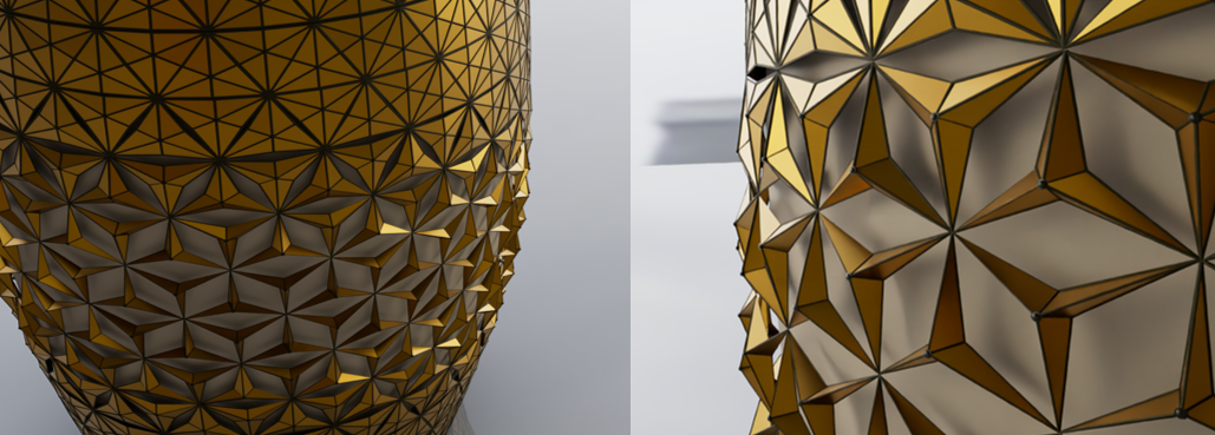

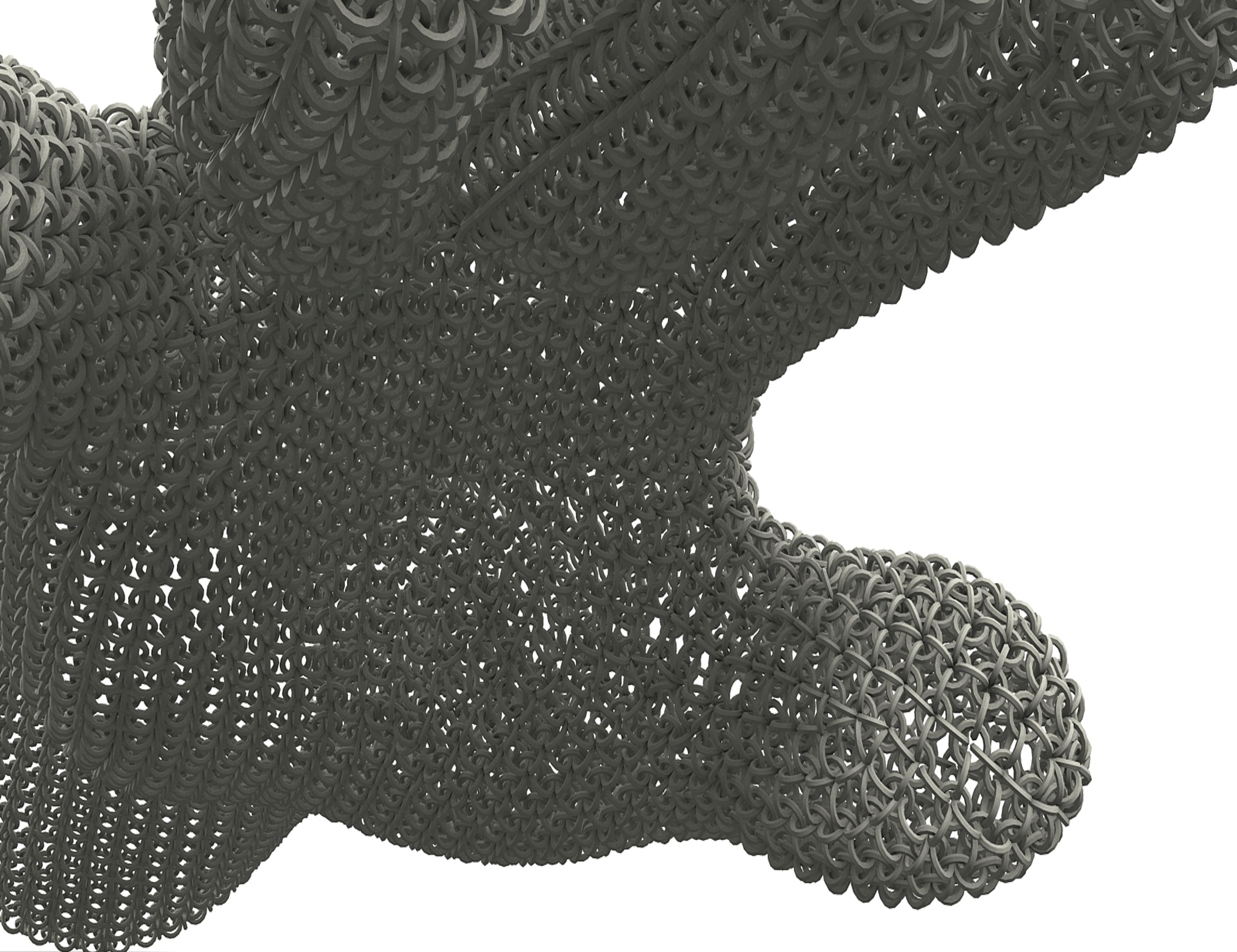

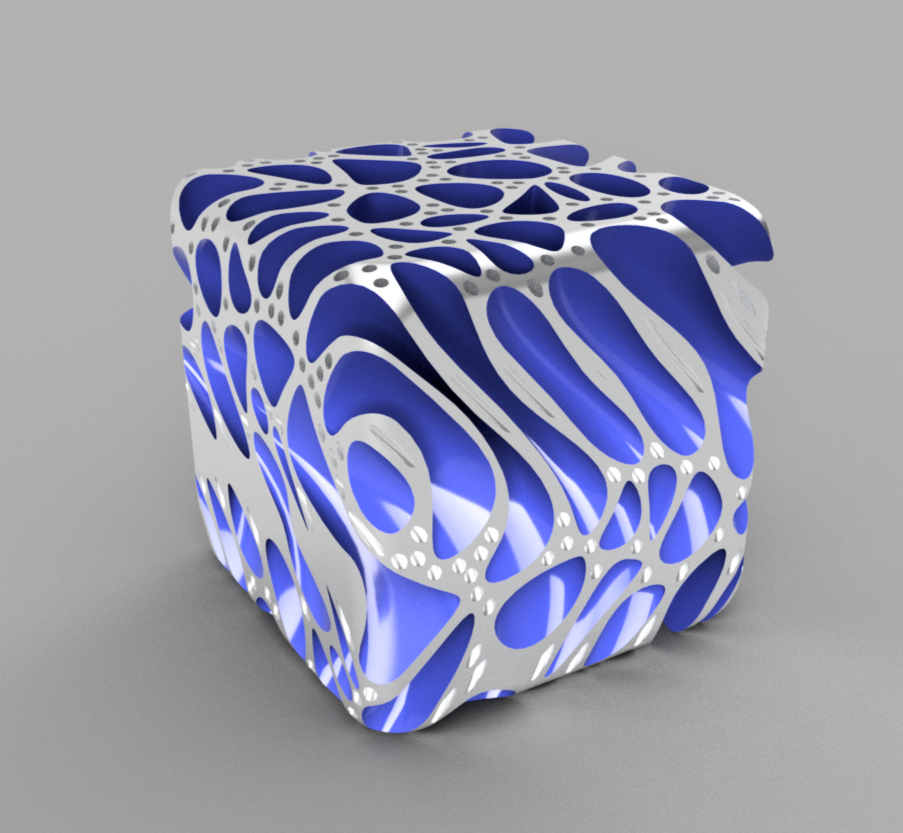

Macro Lattice optimization

Custom Lattice

Conformal Lattice

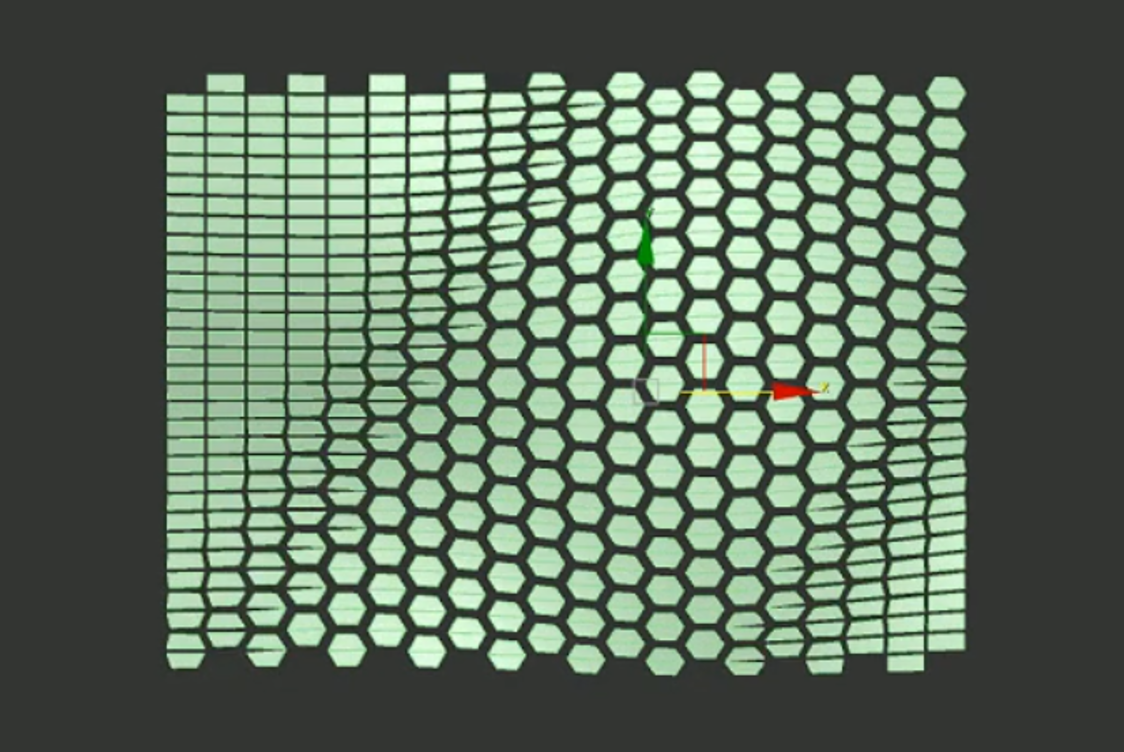

Patterns

Generative Design and Beautification

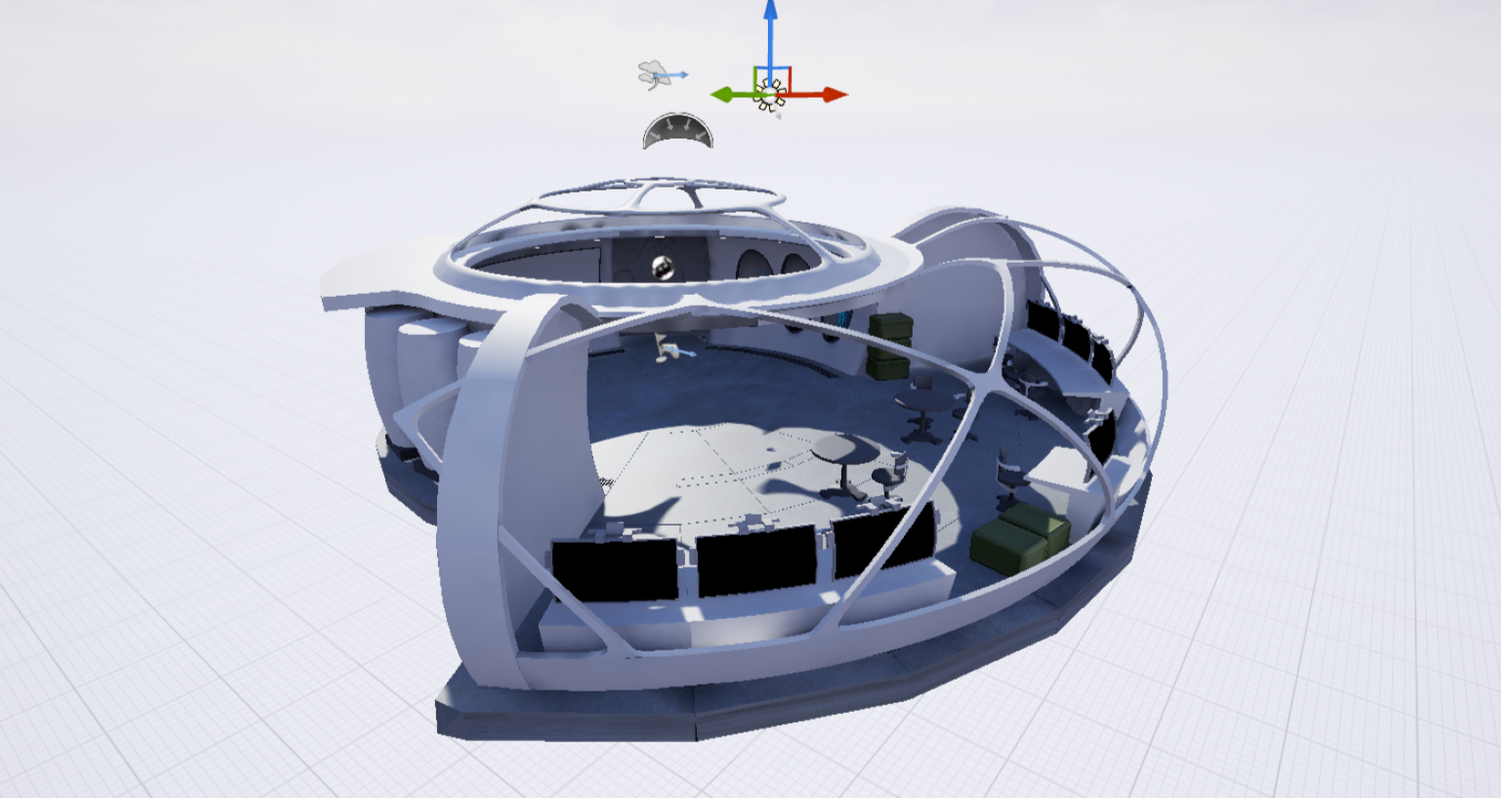

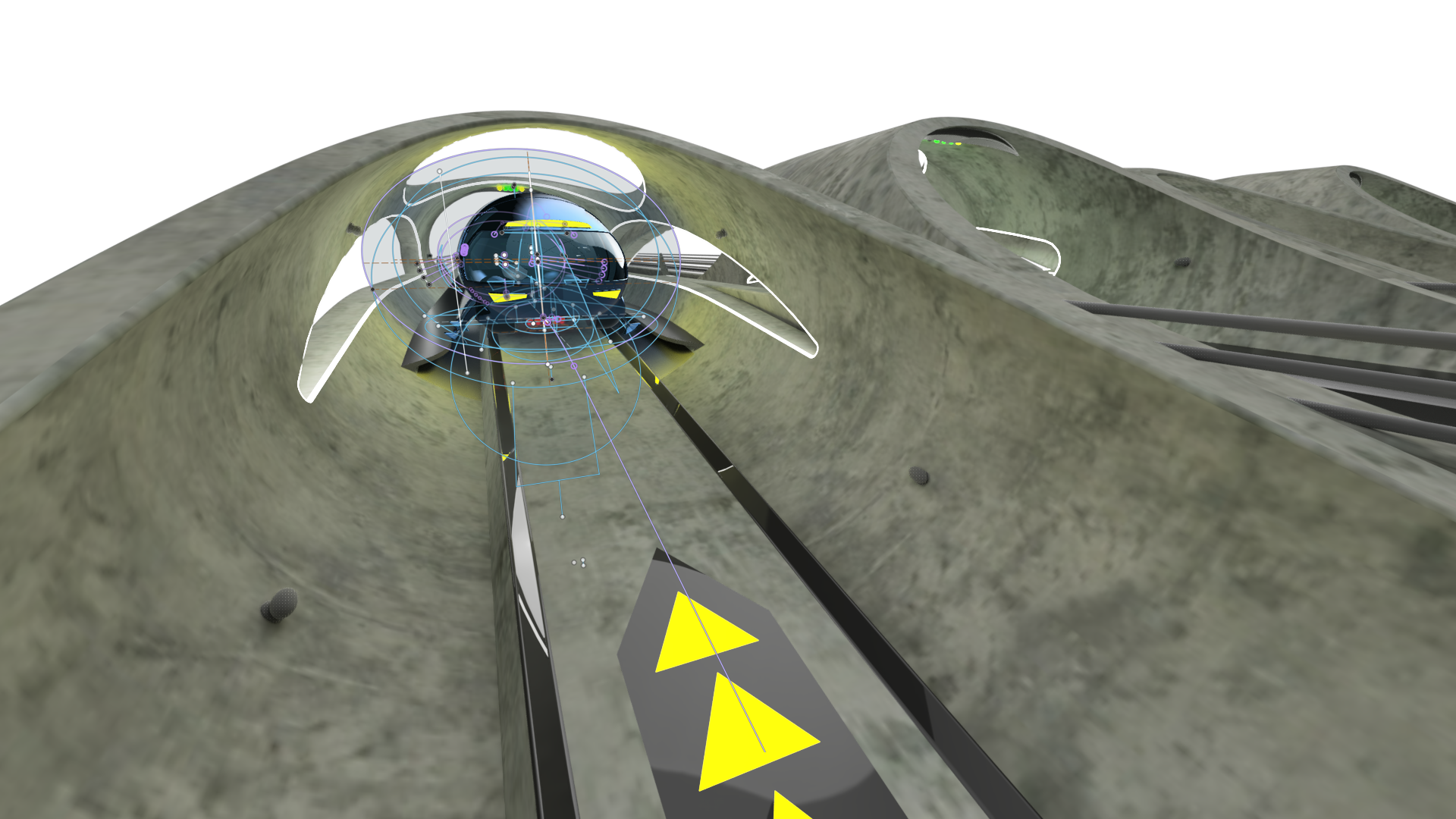

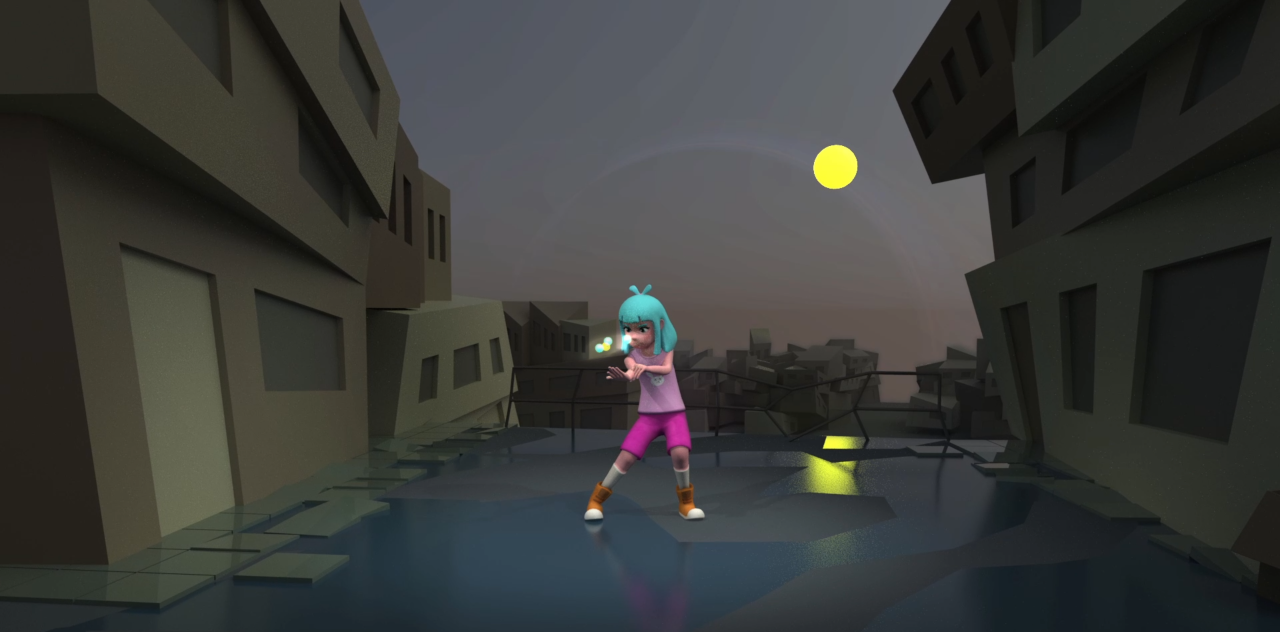

Environments creation for game-engines(test-shots)

Computational Design

Every click generates a new design with the precise request defined by the client for a volume of the internal liquid. (Dynamo, Python, 3D Max used)

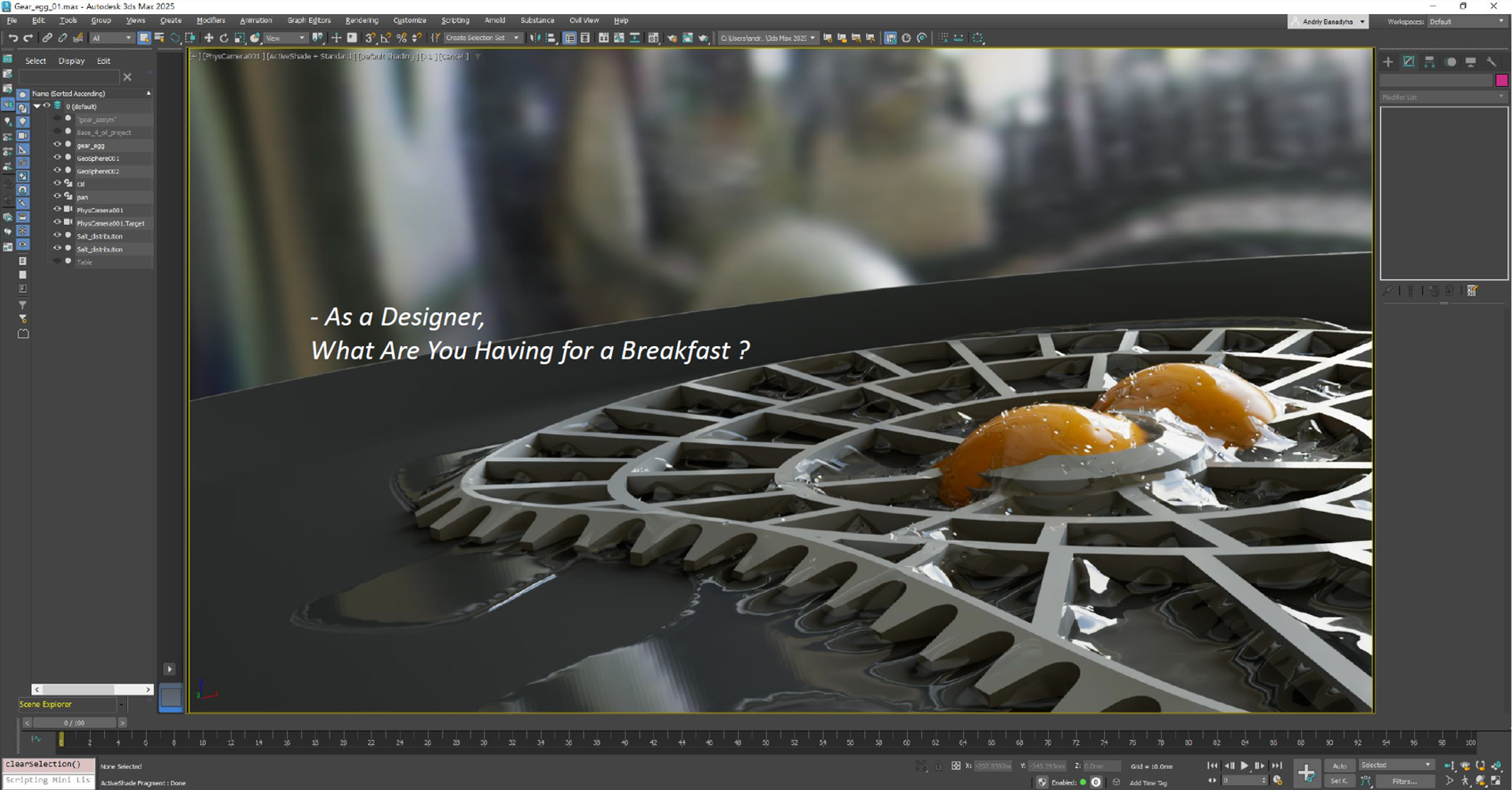

Out of curiosity - mimicked architectural task using simple rules of animation.

Just for fun, the user can control the external shape of the fried egg, number of teeth, number of internal subdivisions and central point.

Output - water-tide solid.

Yolk and salt added in 3D Max.

Custom and experimental projects

Visualization Examples from previous jobs(2006-2009)

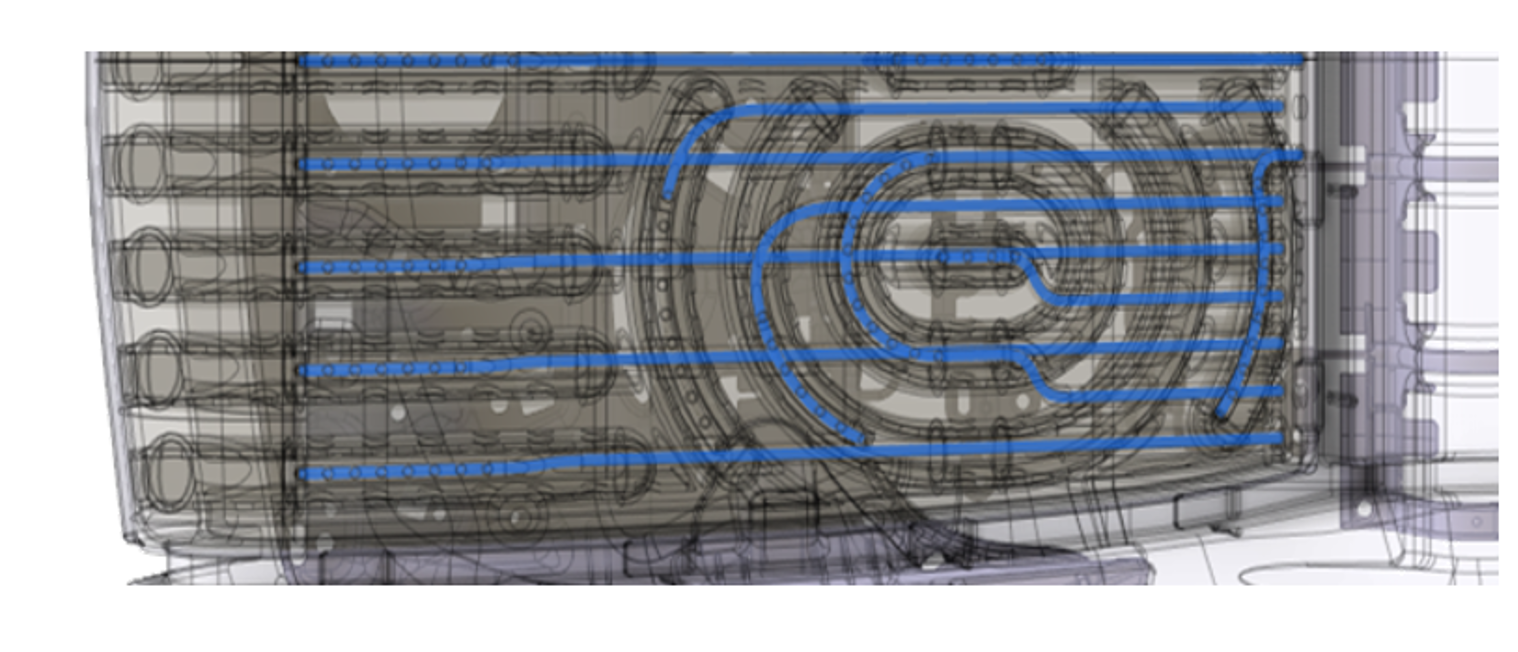

Received model as 3D-CAD.

Textures from photo references.

UV’s and renderings - 3D Max.

Images used as an addition for technical drawings.

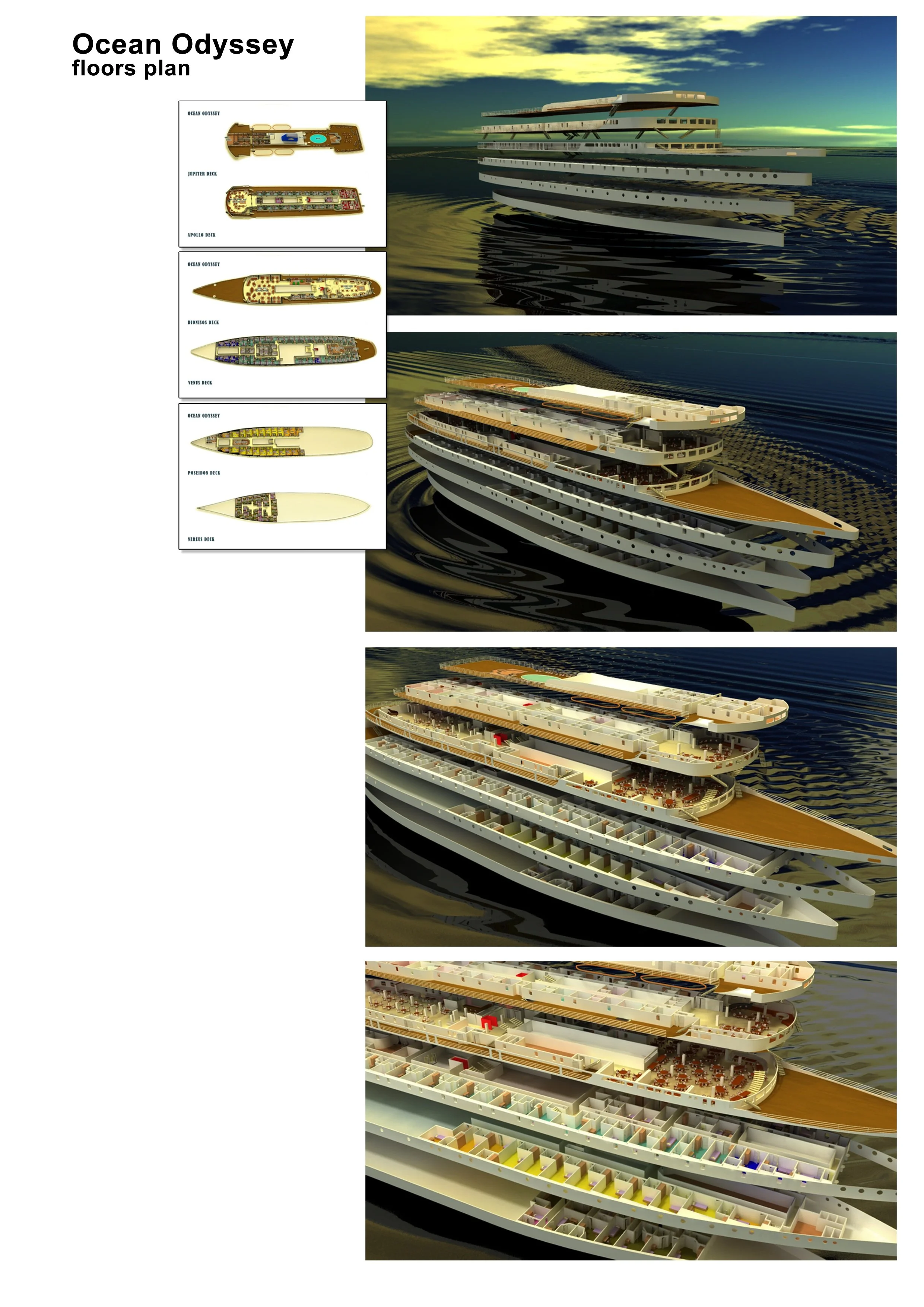

Project created from elevations and photo-references.

Just for Fun (solid and mesh)

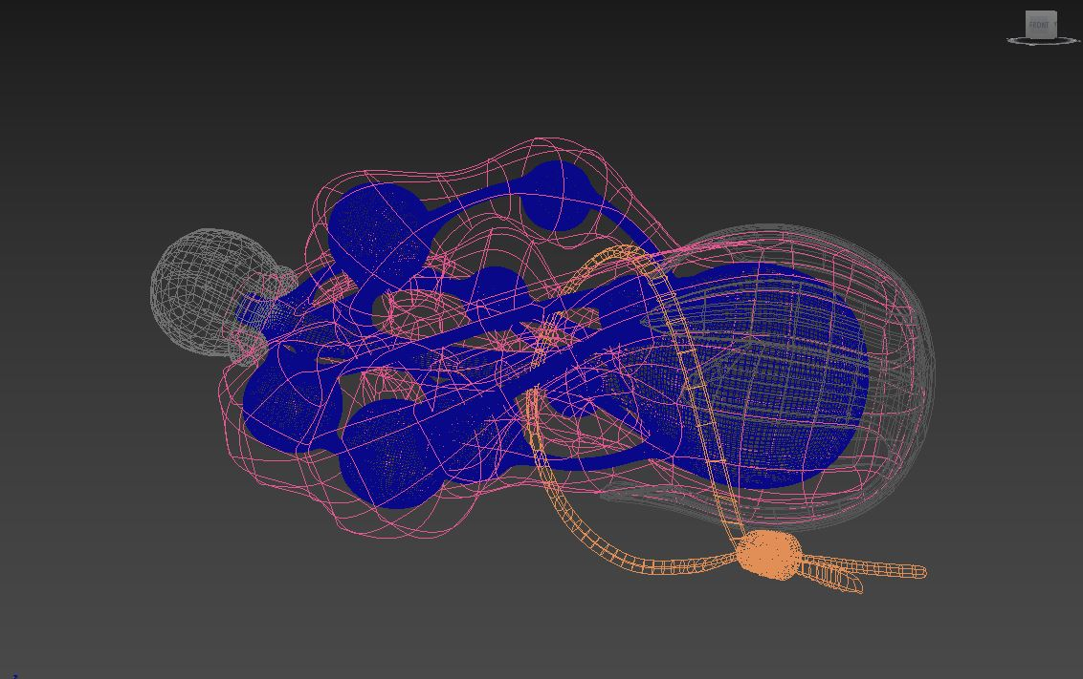

Behind The Curtain

3D Modelling

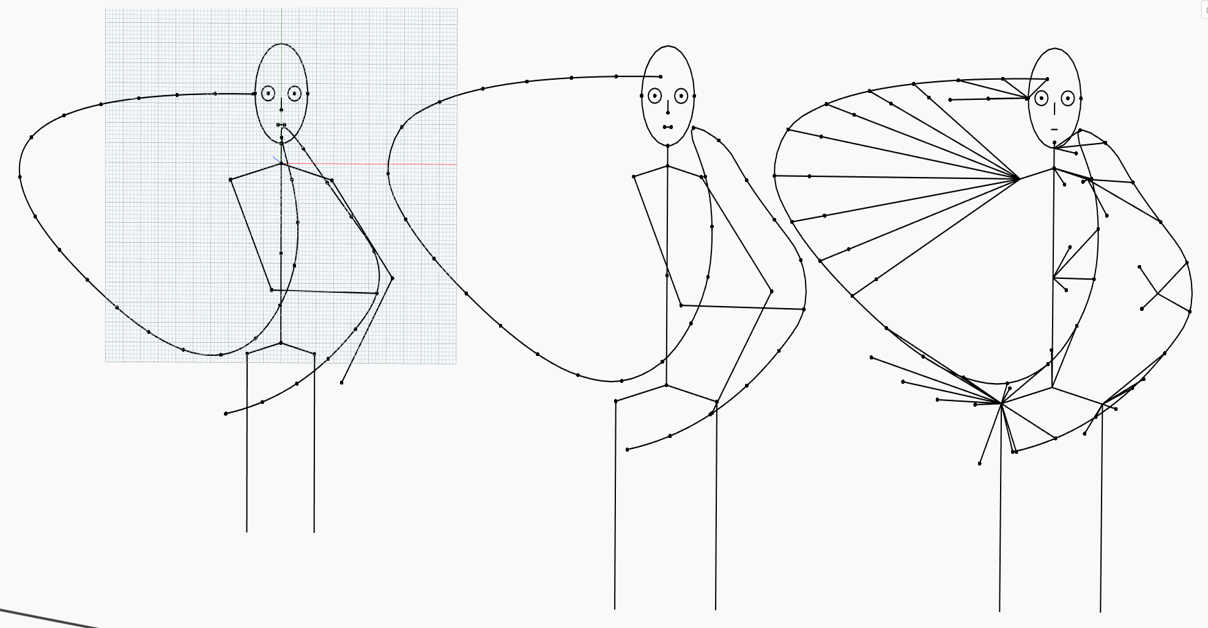

I am not a good sketcher.

It is easier for me to describe an idea

with a mouse and keyboard.

Gestures, mimics - anything is acceptable as a project description from a customer point of view.

When you know your geometry, UV and patterns on top of it goes naturally.

I prefer to know my geometry as deep as I can.

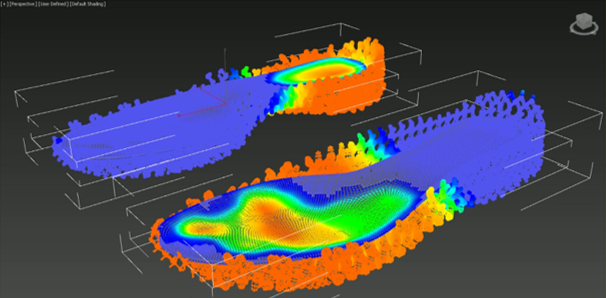

Verification and Validation

Even for a bold, “what If” project - linear static analysis is the first sanity check.

Non-linear analysis is a must for “comfort” projects.

I made a stress-strain device at home involving a drill, scale and homemade-rig. The customer was shocked and loved it and approved the result from it.

Computational Design

Every parametric design is a computational example and must-have when working with customers or manufacturers, in most cases.

Very often, lately, computational Design is my sandbox.

Python makes it easier and tidier.

Knowing pro’s and con’s between solid and mesh makes the experience smoother.

Manufactorability

My Dad and Grandad ware carpenters, so I did not have much of a choice. The smell of the wood in the workshop, understanding the effort and price behind is a very natural thing for me.

Design for 3D-printing and potential CNC requirements make my projects come to life faster.

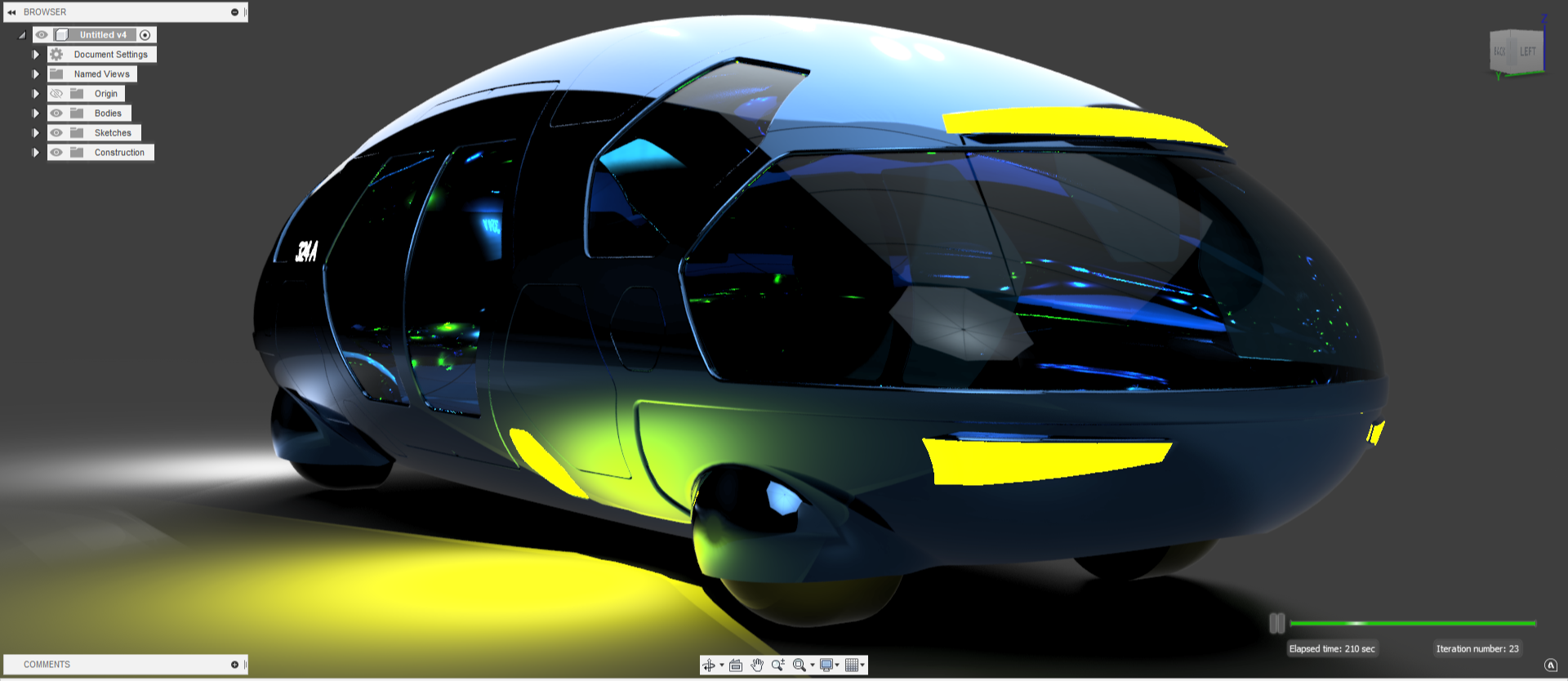

Visualization

Visualization is a “cherry-on-a-top” for a good model.

There are many rendering-engines available. Speed and quality are different, but more or less, the same principles applies behind.

A half eaten sandwich or an abandoned hoover in a background may add more realism to the scene, then carefully balanced light and shaders.

Sustainability

It is not an easy task to throw away a peace of wood for me :)

I am reusing my skills and knowledge on a daily basis - most of the jobs inside our current home - carpentry, plumbing, electrics, tiling, painting are all done by myself (with professional verification - whenever required).

P.S. I have to confess - I hate painting, maybe that is why it starts with “pain”.